In the ever-evolving landscape of electronic waste management, a groundbreaking biological approach is capturing the attention of researchers and industry experts alike. The utilization of Acidithiobacillus ferrooxidans, a bacterium known for its role in bioleaching, is emerging as a sustainable method to recover gold from discarded electronics. This innovative technique not only addresses the growing environmental concerns associated with e-waste but also offers an economically viable alternative to traditional, often hazardous, extraction processes.

The proliferation of electronic devices has led to an unprecedented surge in e-waste, creating urgent environmental and health challenges. Conventional methods for gold recovery, such as cyanidation and pyrometallurgy, involve toxic chemicals and high energy consumption, contributing to pollution and resource depletion. In contrast, biohydrometallurgy leverages the natural capabilities of microorganisms to extract metals, presenting a greener and more efficient solution. Among these microbes, Acidithiobacillus ferrooxidans stands out for its ability to oxidize ferrous iron and reduce sulfur compounds, facilitating the release of precious metals from electronic scraps.

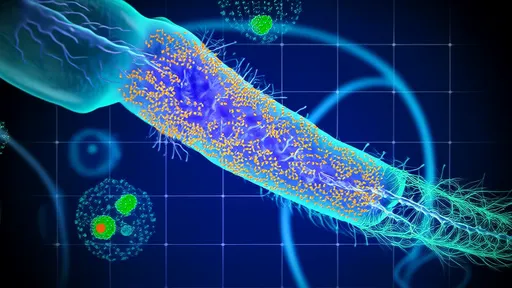

Acidithiobacillus ferrooxidans thrives in acidic environments and plays a pivotal role in the bioleaching process. This bacterium catalyzes the oxidation of iron from Fe²⁺ to Fe³⁺, generating ferric iron, a powerful oxidizing agent that attacks sulfide minerals often associated with gold in e-waste. Additionally, it produces sulfuric acid, which helps maintain the low pH necessary for optimal bacterial activity and metal dissolution. The synergistic action of these biochemical processes enables the efficient liberation of gold particles from complex electronic matrices, making it accessible for subsequent recovery steps.

The application of this bacterium in gold recovery begins with the preparation of e-waste, which involves shredding and grinding to increase surface area for microbial action. The material is then subjected to a bioleaching reactor where Acidithiobacillus ferrooxidans is introduced along with a nutrient medium. Over a period of days to weeks, the bacteria actively degrade the metal-bearing components, resulting in a leachate rich in dissolved gold. This solution can be further treated through precipitation, adsorption, or electrolysis to isolate pure gold, completing the recycling loop.

One of the most significant advantages of using Acidithiobacillus ferrooxidans is its environmental friendliness. Unlike chemical methods that generate toxic residues, bioleaching produces minimal harmful byproducts and operates at ambient temperatures, reducing energy demands. Moreover, this approach can be applied to low-grade e-waste that is economically unfeasible to process through conventional means, thereby maximizing resource recovery and minimizing landfill burden.

Despite its promise, the scalability of biohydrometallurgy for gold recovery faces certain challenges. The process is relatively slow compared to chemical extraction, and maintaining optimal conditions for bacterial growth requires careful monitoring. Researchers are actively exploring genetic engineering and process optimization to enhance the efficiency and speed of bioleaching. Advances in bioreactor design and the integration of hybrid techniques combining biological and chemical methods are also being investigated to overcome these limitations.

The future of gold recovery from e-waste undoubtedly lies in sustainable innovations, and Acidithiobacillus ferrooxidans is at the forefront of this revolution. As technology advances and regulatory pressures mount for greener recycling practices, biohydrometallurgy is poised to become a cornerstone of the circular economy. By turning electronic waste into a valuable resource through natural processes, we not only mitigate environmental impact but also pave the way for a more sustainable and resource-efficient future.

In conclusion, the role of Acidithiobacillus ferrooxidans in recycling gold from electronic waste exemplifies the powerful synergy between biology and industry. This method highlights how harnessing microbial capabilities can transform waste management, offering a path toward environmental sustainability and economic resilience. As research continues to refine and expand this technology, it holds the potential to redefine our approach to resource recovery in the decades to come.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025